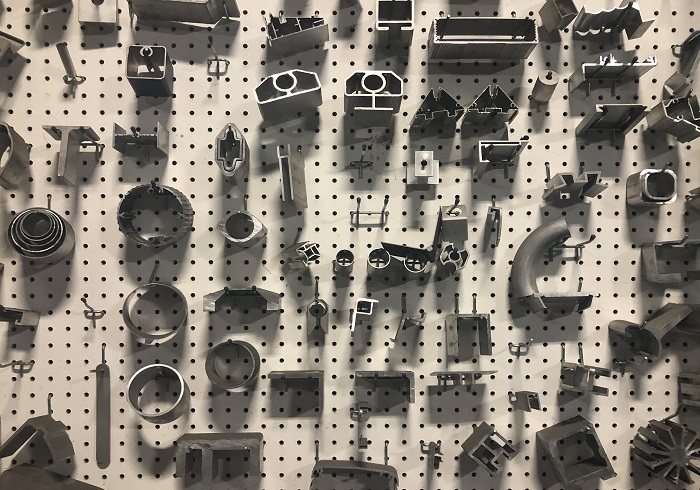

Products and services

Custom Profiles

Bars and plates in alloy 6082, 6026 or other alloys

Zarbana Aluminum Extrusions

Zarbana Aluminum Extrusions was founded in 2005. It was originally introduced as Zarbana Industries, Inc., and was a fabrication-only shop.In 2016, Zarbana was purchased as an offshoot of the Extral Technology Group (producer of complete extrusion systems and aluminum foundries) and operates in the production of aluminum alloy extrusion.

In 2016, a 7" Extral Press Line, in 2018 a 9" Extral Press Line and in 2020 a 20" Press Line were installed.

These presses can meet even the most demanding requests in the extruded profile market.